Zemax software can be used in every step of the optical products simulation process from design development to manufacturing. In addition to optical design using OpticStudio, it provides workflows to seamlessly link OpticStudio design data with mechanical design and manufacturing sites. This reduces the necessity for file format conversion to other software and multiple exchanges of data between designers, significantly reducing man-hours and costs.

Zemax software is highly compatible with Ansys Speos and Ansys Lumerical and can be used for coupled analysis. With a lineup of solutions that can be used in a wide range of optical fields, including illumination optics, electromagnetic field optics, and imaging and wave optics, Zemax contributes to solving the design and development problems for optical engineers.

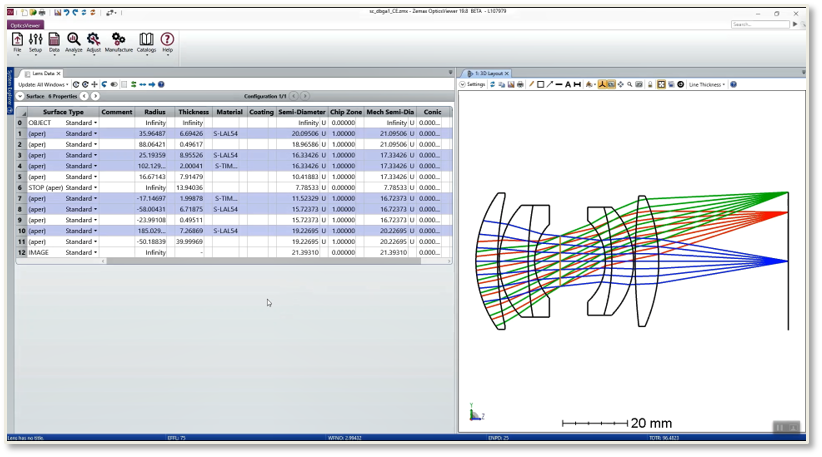

OpticStudio®

Optical Design Software with Extensive Analysis and Optimization Capabilities.

Design and development software for imaging optical systems that is suitable for designing camera lenses, etc.

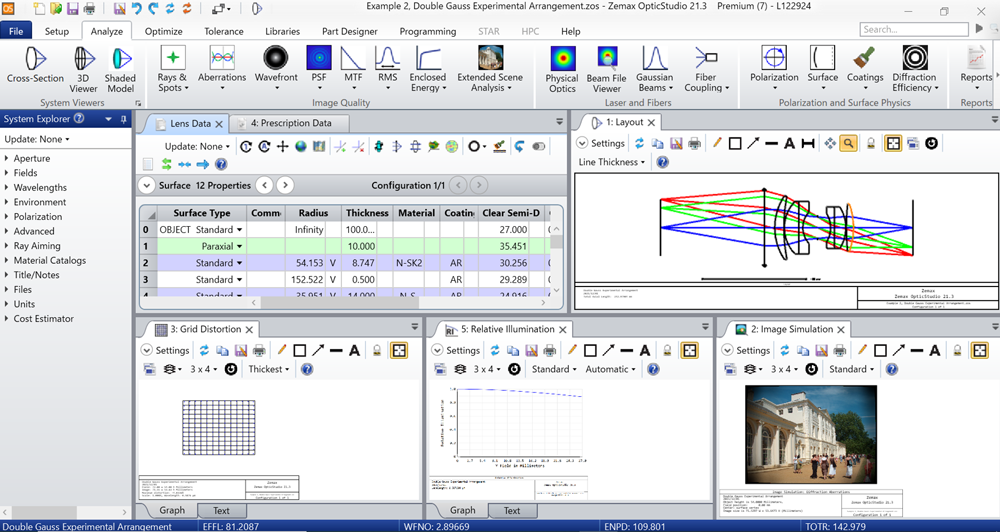

OpticStudio is the industry's leading optical design software and is used in a wide variety of fields around the world, from aerospace and astronomy to automotive, consumer electronics, and biomedical research. Not only can it evaluate the predictive performance of various optical systems, from imaging optics including complex surface geometries to illumination systems, including the effects of stray light*1, but it can also optimize the shape and materials to meet the conditions and performance targets set by the user. In addition, tolerance analysis using design data allows the user to understand the predictive performance of the actual product in advance, thereby reducing the discrepancy between the performance of the design and the performance of the actual product and greatly contributing to the reduction of rework in prototype manufacturing and design.

*1 Stray light: Unnecessary light generated on the surface of the lens barrel of an optical instrument or at the edge of a lens. In the case of a camera, it can interfere with shooting as intended.

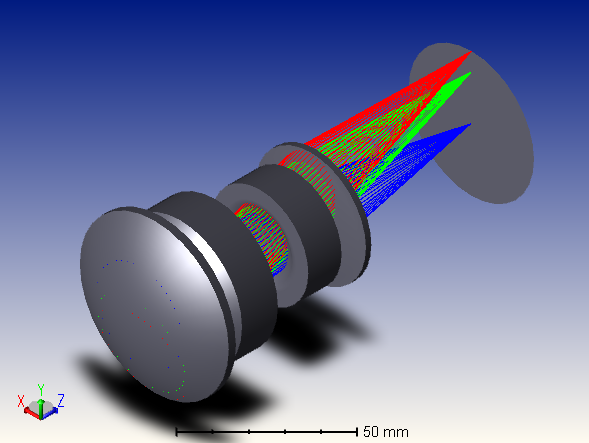

Double Gauss lense design in OpticStudio.

OpticStudio STAR Module™

Expansion module to support structural and thermal performance analysis.

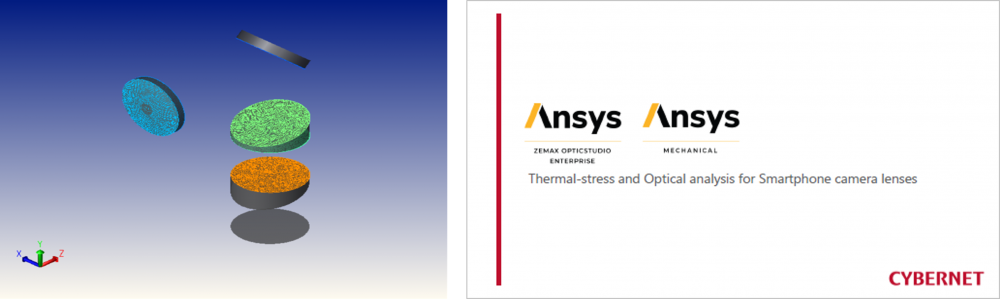

The OpticStudio STAR (Structural*2, Thermal*3, Analysis and Results) Module is an extension of OpticStudio that allows you to visualize within OpticStudio the impact of structural and thermal loads on the optical design of a component. You can visualize the impact of structural and thermal loads on the optical design of a component within OpticStudio and perform structural, thermal, and optical performance analysis based on FEA*4 data sets. Since there is no need to use other dedicated software for structural and thermal analysis, design can be done seamlessly within OpticStudio.

*2 Structural analysis: To analyze the possibility of shape deformation or fracture when a part is subjected to a load.

*3 Thermal analysis: Analyzing the physical changes that occur when a part is heated or cooled.

*4 FEA (Finite Element Analysis): A method of dividing a target model into small parts and analyzing the properties of each small part.

Optical, Structural, and Thermal analysis in STAR Module using FEA data.

OpticsBuilder®

Optical mechanical design software that can convert optical design data directly into CAD data.

OpticsBuilder is software that connects the design of optical components such as lenses with the design of peripheral components that need to be drafted in CAD. By using this tool, optical design data from OpticStudio can be converted to CAD data and used to design peripheral components, allowing CAD users to design components efficiently and with predictive accuracy without the need to recreate optical components in CAD software.

OpticsBuilder can convert optical design data from OpticStudio to CAD data and use it for designing peripheral components.

OpticsViewer®

Optical Design Data Viewer for Manufacturing Engineers to Check Design Data in the Field.

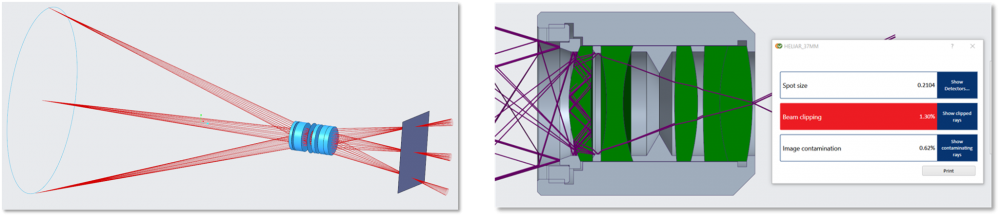

OpticsViewer is a viewing software that allows optical designers to view the design data created in OpticStudio directly on the manufacturing floor. The viewer allows manufacturing engineers to open the OpticStudio design data directly and communicate with the designer while viewing the complete picture of the product, including part geometry, combinations, dimensions, and materials. This helps speed up the product development process by reducing miscommunication and unnecessary repetitive tasks.

OpticsViewer user interface.